Description

Three standard versions of the Straightpoint loadpin are available:

- RF – Long range 2.4GHz version providing industry leading wireless range of 1000m or 3280ft to SP’s SW-HHP handheld or INSIGHT software

- Bluetooth output and can be connected to any smart phone running our free HHP app on iOS or Android at ranges up to 100m or 328ft.

- Cabled Connection with mV/V or analogue or digital output. Subsea option also available.

Long range 2.4GHz version providing industry leading wireless range of 1000m or 3280ft to SP’s SW-HHP handheld or software options.

– Bluetooth output and can be connected to any smart phone running our free HHP app on iOS or Android at ranges up to 100m or 328ft.

– Cabled version with mV/V or analogue or digital output. Subsea option also available.

Often a customised design they are manufactured in-house from 17-4PH stainless steel and are normally supplied complete with an anti-rotation plate as a cabled or wireless solution.

Built to withstand the harshest environments in industries such as marine, offshore oil and gas or construction they are suitable for use in exposed situations and can be supplied as a subsea product with SubConn connectors to withstand immersion in seawater to extreme depths.

Straightpoint cabled Loadpins are typically connected to Straightpoint’s range of handheld displays or may be supplied with a vast array of output formats to include mV/V, RS-422, RS-485, utilising the ASCII, MODBUS TRU and CAN-BUS protocols or an analogue output such as 4-20mA for PLC integration.

Note: Please advise cable configuration on order – Radial or Axial Pin exit.

Standard Loadpin General Description

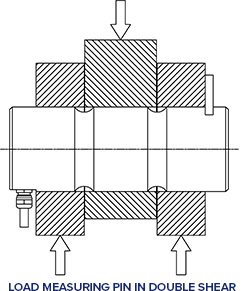

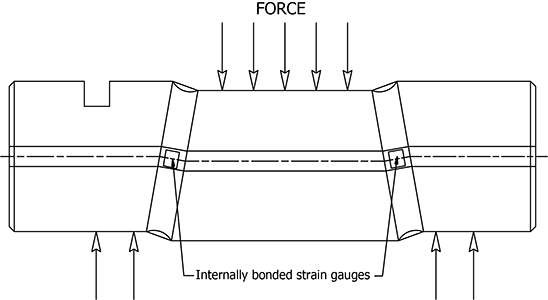

A loadpin senses the force applied across it, via strain gauges installed within a small bore through the centre of the pin. Two grooves are machined into the outer circumference of the pin to define the shear planes, which are located between the forces being measured.

Load Pin Environmental Protection

As the instrumented area of the load pin is totally contained within a small central bore, the load pin sensor is inherently waterproof. Manufactured from special stainless steels, fitted with welded or `O’ ring sealed end caps and with special attention to the signal cable glanding, a very high operating reliability can be guaranteed even for load pins operating underwater.

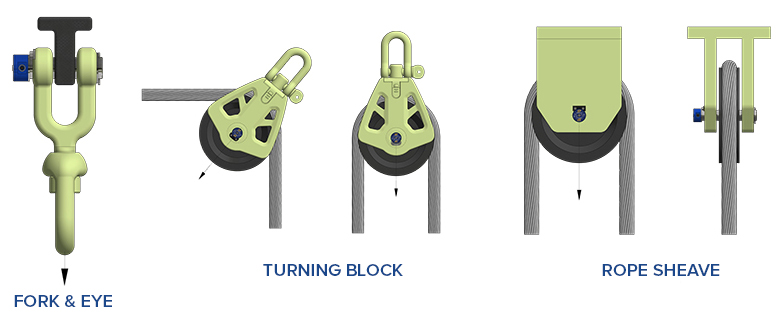

Loadpin Typical Locations

If a pin exists within a defined load path or can be fitted to experience a force, then a Straightpoint Load Pin can be installed to monitor that load. The sketches below show typical locations for load pins.