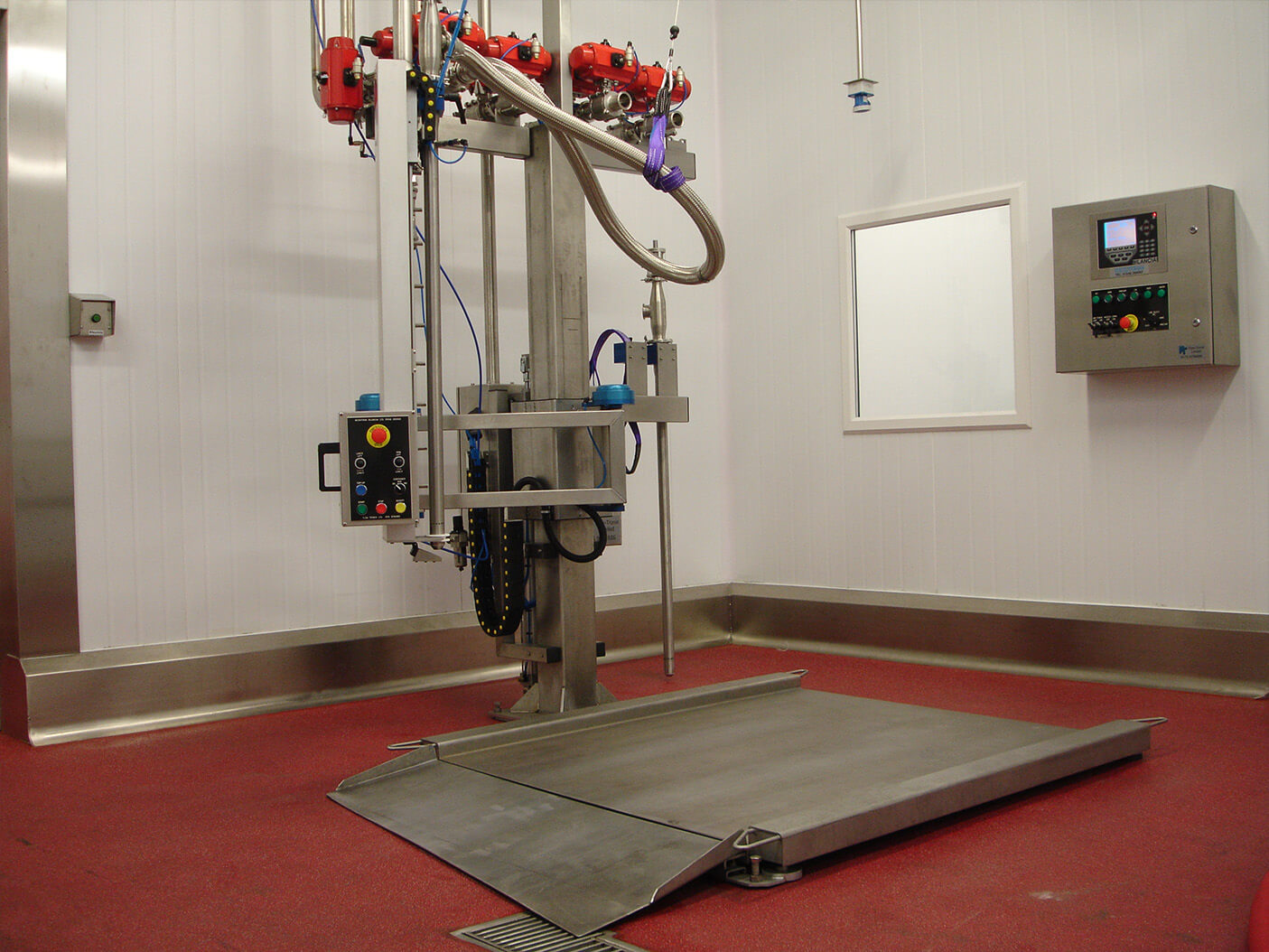

Description

Main Features

- Easy strip down nozzle for cleaning

- Multi-On-Pallet

- Suitable for none foaming (Top Fill) & foaming (Bottom Fill)

- Weights and Measures (DTI) approved

- ATEX compliant

- Mobile platforms complete with wheels or fork lift points

- Nozzles manufactured from 316 stainless steel, Hastelloy or PVDF with PTFE and Viton seals

- Interfaced with weigh platform, flow meter or mass flow meter

- Choice of weigh indicators / platforms or alternatively use your existing equipment

- Internal opening nozzle for open top containers / pails (optional)

Capacity

Weigh range of 20ltr – 1000ltr+

- 16 x 20ltr/25ltr containers (max 2 layers total of 32 per pallet)

- 4 x 205ltr drums

- 1 x 1000ltr IBC container

Optional Extras

Filling Nozzle

The filling nozzle is made from 316 stainless steel as standard, we can also manufacture these in PVDF, PVC, HASTELLOY and PTFE, there are 2 types of filling nozzle; external opening (fitted as standard) or internal opening (used on open top pails/drums), these can be either top fill for non-foaming products or bottom fill for foaming.

Lift with Weight

When using our bottom fill nozzle we have the capability of a lift with weight operation, using our standard indicator you can adjust the target weight to control the lift set points, enabling you to keep the filling nozzle out or In of the product as much as you require.

Overfill Protection

The overfill protection system is designed into the filling nozzle; this system would/could be used as a fail safe shut off should there be a fault during a fill or to stop you filling the same container twice.

Nitrogen Purge

The nitrogen purge system has been designed into the filling lance and is used prior or during a fill process.

Clip Attachments

The CIP attachment is connected onto the bottom of our filling lance to enable the waste product/water that is used to clean through the system to be dispersed into a waste container or drain.

Fume Extraction

We have available 2 types of extraction hoods that we can fit, these fit around the filling nozzle sitting just above the bung hole.

Pumps

All of our filling machines can be interfaced with a variety of pumps whether new or existing.

Skid Mounted / Mobile

The skid is designed to be movable there are a few options below:-

- Built with fork lift truck mountings + leveling feet

- Built with wheels + leveling feet

- Built on a base to hold a pump and fixed directly to the floor.

Flexable Hose

Flow Tronix Ltd. can also provide flexible hoses for all needs such as Flange, BSP and Union Clamp end connections, various braiding and internal linings available.

Earth-Rite Systems

The Earth-Rite PLUS is an extremely versatile system that may be used to monitor static earth conditions on a wide range of plant equipment, including Mobile Tanks, Railcars, IBC’s, Drums and Containers.

Conveyor Systems

Our filling systems can be interfaced in to conveyor systems either Powered or gravity.

Please click here for the FT-100 filling system technical drawing …..