Description

DOSAGE FUNCTIONS

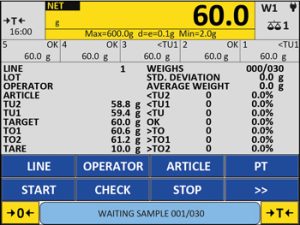

- 2 selectable operation modes:

– Instantaneous reading of the flow, in kg/h or t/h with displaying of the status of the system and of the dosed total.

– Adjustment of the dosage hourly flow, in function of the pre-setted target, with PID algorithm. - Visualisation of the hourly flow graph and wide range of data displayed on the display.

- Calibration of the flow reading function, for controlling the dosage performances.

- Reading filter of the hourly flow with configurable incidence and speed depending on the system.

- Programmable dosage target upon weight or upon time, with relative contact.

- Programmable start dosage delay, for synchronisation of various E-BELT systems in the dosage of material mixtures.

- Management of the slow flow with programmable activation threshold, for more precise dosages.

- Management of the dosage total under way and general total of dosages, printable and clearable independently from each other.

- Management of the automatic dosage from remote master or through Profibus DP or Modbus RTU protocol.

- Printing of the dosage data and the total.

- Completely programmable printouts, for compatibility with any ASCII printer manageable through the serial port.

DATABASES

- Database of 100 products with: 5 alphanumeric description, hourly flow target, weight dosage target and initial value analogue output.

- Manual programming of the products or throught PC software (Dinitools).

I/O FUNCTIONS

- Activation cycle, START / RESTART dosage, PAUSE / RESET cycle and unloading of the belt out of the cycle, through external inputs.

- Impulse counter of the accumulated quantity through relay contact, for direct communication with PLC or external devices.

- Relay contacts dedicated for the complete management of the alarms and the blocks for off weight, off flow and belt side-slipping.

- Input and output with programmable functions.

- 16 bit analogue input (optional) for programming the hourly flow target.

- 16 bit analogue output (optional) proportional to the hourly flow (lector mode) or programamble for regulating the dosage speed (regulator mode).

- Serial communication protocol for programming the products and reading the cycle status.

- SYSWAY and MODBUS communication protocol for programming the dosage data and managing the cycle.

- External Profibus interface (optional), for programming the dosage data and managing the cycle.

- Optional Bluetooth connection, for quick wireless programming of the product, through PC or PDA.

SYSWAY, MODBUS, PROFIBUS FUNCTIONS

- READING THE DATA:

– net weight

– instantaneous flow

– value of the instantaneous pid

– partial total

– general total

– status of the optoisolated inputs

– status of the optoisolated outputs

– flow target (for the controller modes)

– minimum flow, maximum flow

– dosage time

– target to be dosed

– set point enabling/disabling value

– status of the scale - AVAILABLE COMMANDS:

– dosage Start/Stop/Reset

– programming of flow target, target to be dosed and dosage time

– print format

– reset of accumulated totals

– setpoint programming

Please click here for the “E-Belt”: Software For 3590E/CPWE Indicators For Management Of Continuous Dosages on Belt Datasheet…